You know, it dawned on me that we have spent the last three years talking about all this great food packaging, but we really have not described or shown you how we actually make our products. I don’t know about you, but I find myself drawn into watching those cable shows on how various things are made, like a bug to a shiny light. Somehow I always come away feeling better that I now know how glass Christmas tree ornaments are actually made. Along that same vein, allow me to give you a crash course in how our products are made.

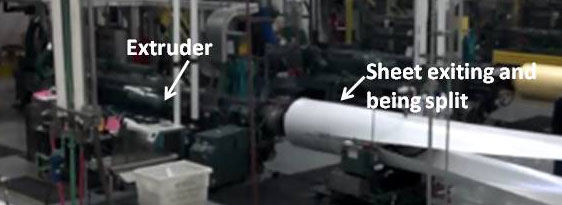

Although it is a highly sophisticated and complex transformation from resin pellets to finished parts, it can really be broken down into two main functions. Extrusion and thermoforming. In the extrusion process we take the raw material which we call resin (they look like little pellets), and melt them down to form smooth sheets of material. To do this the resin enters the extruder at one end where it is pushed forward via a screw. As it’s pushed forward a combination of heat and pressure produced from the screw, slowly melts the resin. When the molten material reaches the end of the extruder, it exits over the die which gives it its new shape…a sheet of plastic. Here are a couple of pictures that will help aide in the description. In this shot we see the actual extruder and the foamed polystyrene material exiting, being split into two sheets and heading toward the S-wrap.

Following that process further, here’s the end of the extrusion line as the sheet exits the S-wrap, which is a devise used to control the density of the sheet itself. This is one way we control the weight of a part. From the S-warp, the sheet heads into the winder where a large roll of material is ready for storage and use later during the thermoforming process.

Now that we have rolls of material (polystyrene, polypropylene, PET) we can move on to the thermoforming process. As its name implies we heat up the sheet and form it into the shapes you know as our product offering. The large rolls are placed at the beginning of the thermoforming line where we feed the sheet through an oven that warms it up to a desired temperature which makes it easy to stretch and form. As the sheet exits the oven it heads into the former where the parts are formed into say a hinged take-out container. From there, the now formed parts which are still attached to the sheet head into the trim press where they are cut away from the sheet and pushed out to a packing table where, you guessed it, they are packed up for sale.

Hopefully this brief glimpse into our production world will give you a better understanding of just how our products are made.